Technology

General

PRANS HSS X8 unit is intended for use in the open spaces and in field conditions. The method of thermo-abrasive cleaning of the steel surface before its coating is the most effective technique currently in use.

Passing through a gas flame plume formed in the combustion chamber of a supersonic apparatus, the abrasive particles are accelerated to high speeds and heated to 200-250°C, while the moisture and organic compounds contained in the stream of compressed air and abrasives are completely removed. Removal of contaminants from the treated surface occurs at high temperatures, with high energy impact on the surface layer and in an environment with low oxygen content, and all these create optimal conditions for the subsequent application of a protective coating.

A remarkable advantage of the technology implemented with the units of PRANS HSS series is that surface preparation and coating are carried out by one device. This allows application of coatings onto the prepared surfaces without time delays, during which the surface layer of the prepared objects can get contaminated and oxidized. Avoiding this, the quality of the coating is stable and impeccable.

Cleaning and coating process video:

Two Processes. One Unit

The PRANS HSS X8 unit is designed for thermo-abrasive cleaning of surfaces and structures made of various materials from any coating, oxide films, limescale, fuel oil deposits and other contaminants with subsequent application of a protective zinc coating onto the cleaned metal parts.

Switching between cleaning and coating processes with no delay.

Switching process video:

Advantages

Units of the PRANS series are multifunctional and at the same time their technological process is based onto many heterogeneous physical phenomena (processes).

The technology of PRANS allows to carry out high-quality cleaning, preparation and activation of surfaces for the subsequent application of metal coatings – zinc, aluminum, alumino-zinc, copper.

- High fire safety

- Easy to operate and maintain, easy to adapt to the technological process

- Ability to apply different materials Zn, Al, Cu (metallization), also possible to apply composites (heterogeneous coatings)

- One units performs both processes, surface cleaning (sand blasting) and materials application (metallization)

- High profitability of work with these units and their high efficiency (top among sand blasting equipment and metallization plants on the market)

- Minimized time between preparation of the surface and application of the protective coating

- The degree of cleaning treatment is not lower than Sa-3 according to ISO 8501-01 and higher

Why PRANS?

Why is the metallization or coating technology of the PRANS unit better than other alternative techniques of application or other coating units currently on the market?

- Significantly lower porosity of the coating (less than 1% vs. 15-30%)

- Significantly higher adhesion of the coating to the base (several times higher, tens of megapascals, against a few megapascals)

- Convenience and efficiency of superb quality surface preparation before coating, which is nonexistant within alternative methods.

- The need for separate equipment to provide surface preparation (usually, sandblasting equipment, which does not provide such a quality as the technology of PRANS)

- High performance and the ability to apply higher thickness of the coating layer

- Relative safety and simplicity of equipment.

Before & After Samples

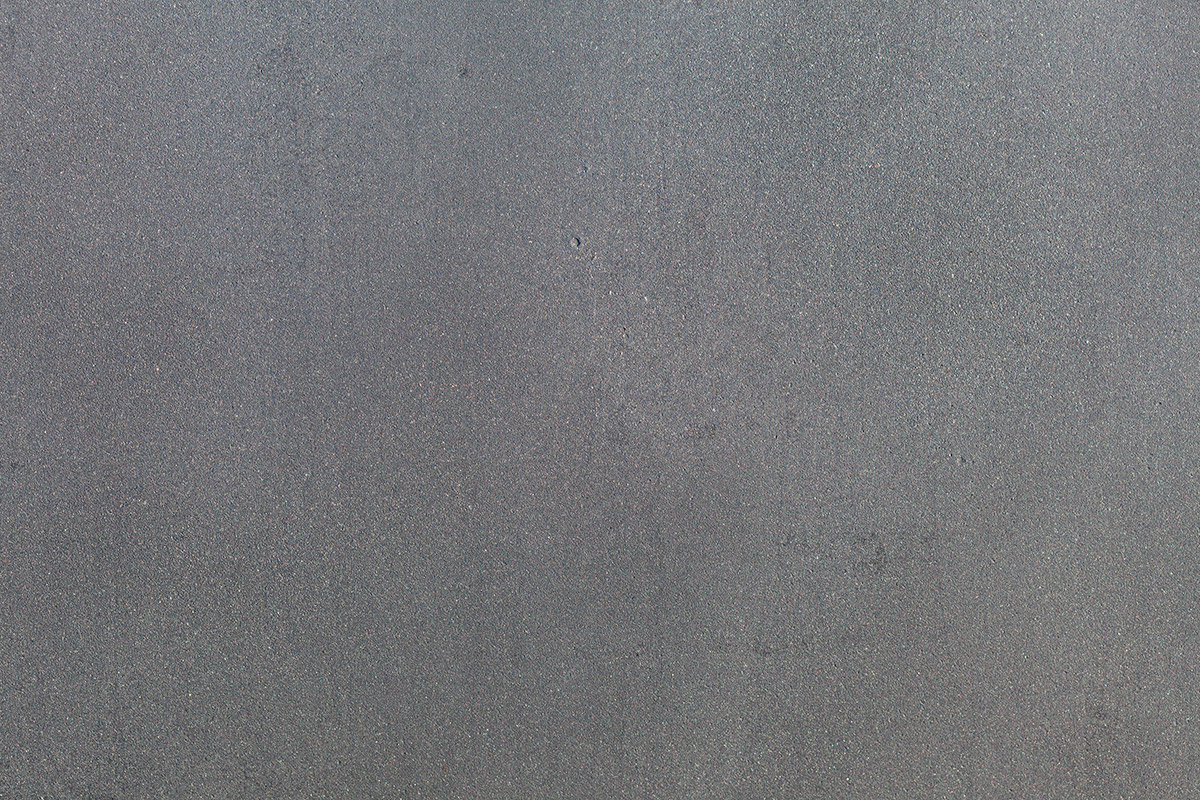

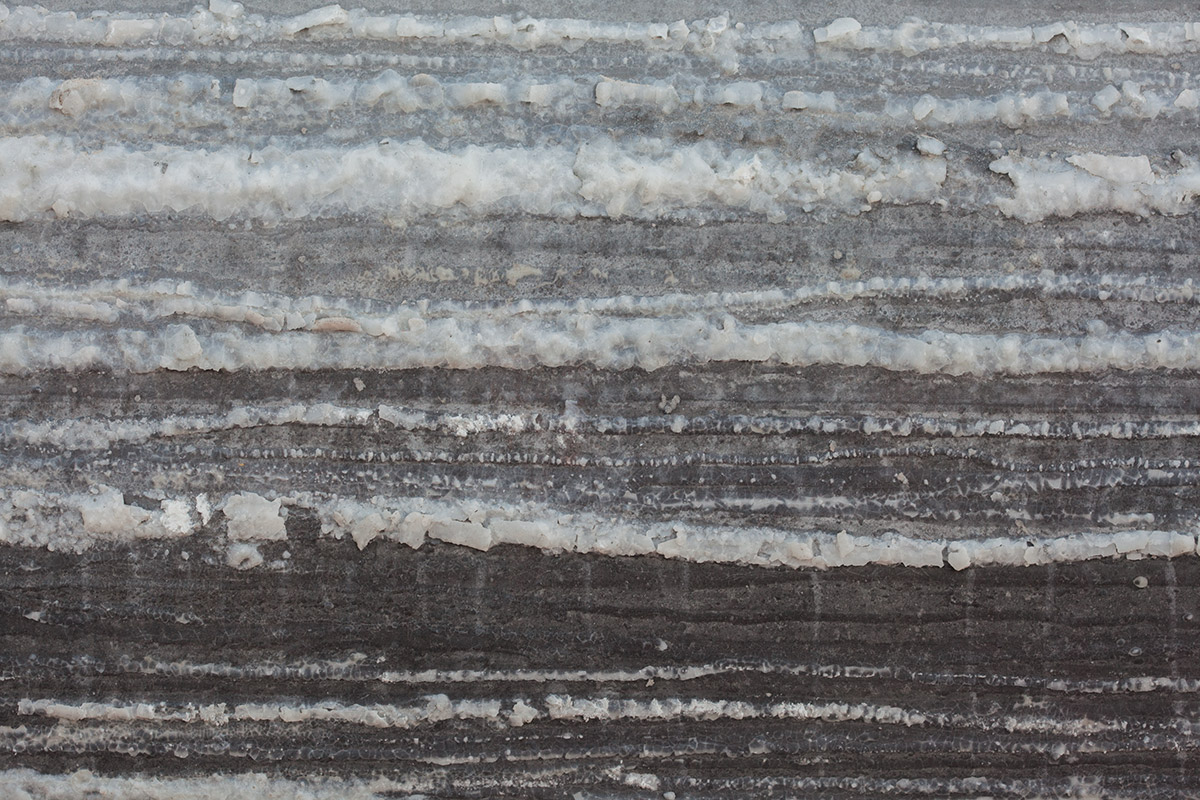

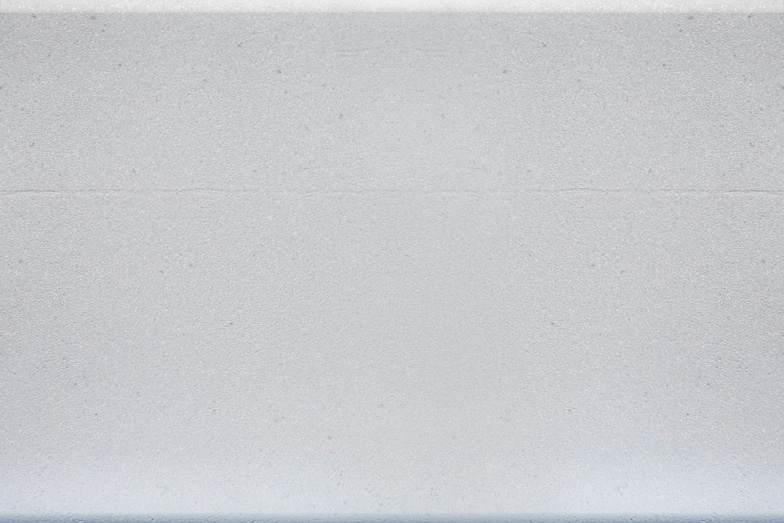

Cleaned with HSS

Cleaned with HSS

Original Surface

Original Surface

Cleaned with HSS

Cleaned with HSS

Original Surface

Original Surface

Cleaned with HSS

Cleaned with HSS

Original Surface

Original Surface

Efficiency

Considering the fact that working with a compressor of the given performance can increase the power of the outgoing jet from the nozzle 10 or more times by means of directly converting the chemical energy of the hydrocarbon fuel into thermal and kinetic energy, we achieve better results.

With the help of our technology and equipment, the speed of the gas phase of the jet can reach 3-4 Machs (more than 1000-1300 m/s), which is unattainable in conventional sandblasting machines.

Thanks to the technology, consumption of any kind of abrasive for high-quality surface preparation is several times less.

Questions & Answers

Why the surface cleaning (sand blasting) with the PRANS unit is better than other alternative coating methods or other coating units on the market?

What to remember:

- Considering the fact that working with a compressor of the given performance it is possible to increase the power of the outgoing jet from the nozzle 10 or more times by means of directly converting the chemical energy of the hydrocarbon fuel into thermal and kinetic energy, we achieve better results.

- The speed of the gas phase of the jet can reach 3-4 Machs (more than 1000-1300 m/s), which is unattainable in conventional sandblasting machines.

- Traces of bitumen, oil and moisture are easily removed from the surface. Easily achieved dedusting and degreasing of the surface in an oxygen-deficient environment.

- Possibility of implementing a thermal shock cleaning technology and ease of implementation, in case necessary, of the powerful water-abrasive cleaning (Rebinder effect).

- The quality of surface treatment is guaranteed at the level SA 3 and higher (a potential of 0.7-0.8 V is formed on the surface) without any kind of contamination and oxide films

- Consumption of any abrasive required for high-quality surface preparation is several times less compared to peers.

- Possibility of relatively easy control of the degree of roughness and profile of the prepared surface due to changes in the power of the flowing stream, its shape, dispersion and nature of the abrasive.

- There is no need to impose strict requirements on the preparation of air at the input (installation of high-quality moisture and oil separators is not required.

Is it possible to use the names of the methods of material application, metallization and zincing, in relation to the PRANS unit? Or how to correctly name the method of protective materials application with the PRANS unit?

Units of the PRANS series are multifunctional and at the same time their technological process is based onto many heterogeneous physical phenomena (processes).

Basic processes:

- Thermal shock, multi-phase supersonic abrasive blast treatment and activation of the surface

- Gas dynamic (supersonic, closer to cold) spraying of powdered materials

- High-speed thermal diffusion coating (mainly zinc). The process is conducted mainly in semi-closed reservoirs with the short-term creation of a high-temperature zone close to the detail being sprayed (300-400 degrees Celsius and more) and intensive heat and mass transfer of the fresh mixture to the surface of the detail being treated.