About

Cleaning and coating process video:

ADVANTAGES

High Performance

High performance and ability to apply thick coating layer

Low Porosity Of The Coating

Substantially lower coating porosity (less than 1% vs. 15-30%).

High Adhesion Coating

Significantly higher adhesion of the coating (many times higher, many tens versus just a few megapascals)

Safe & Easy

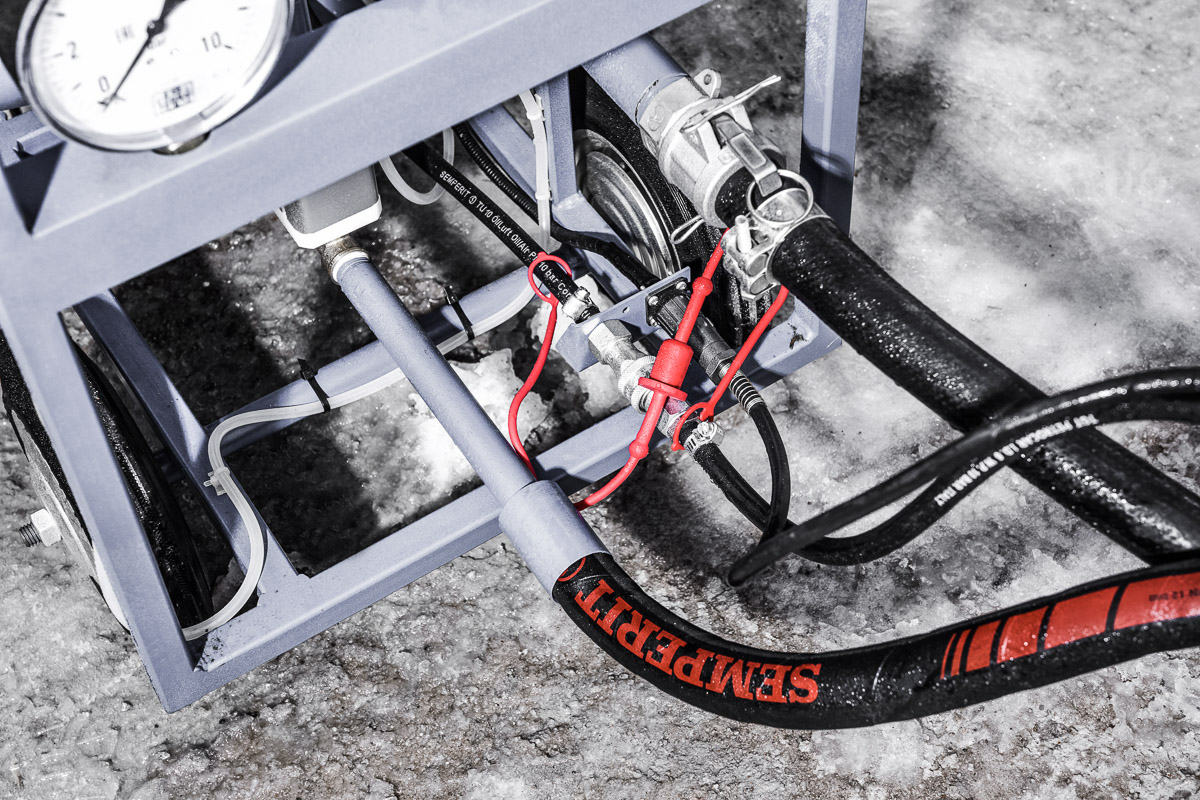

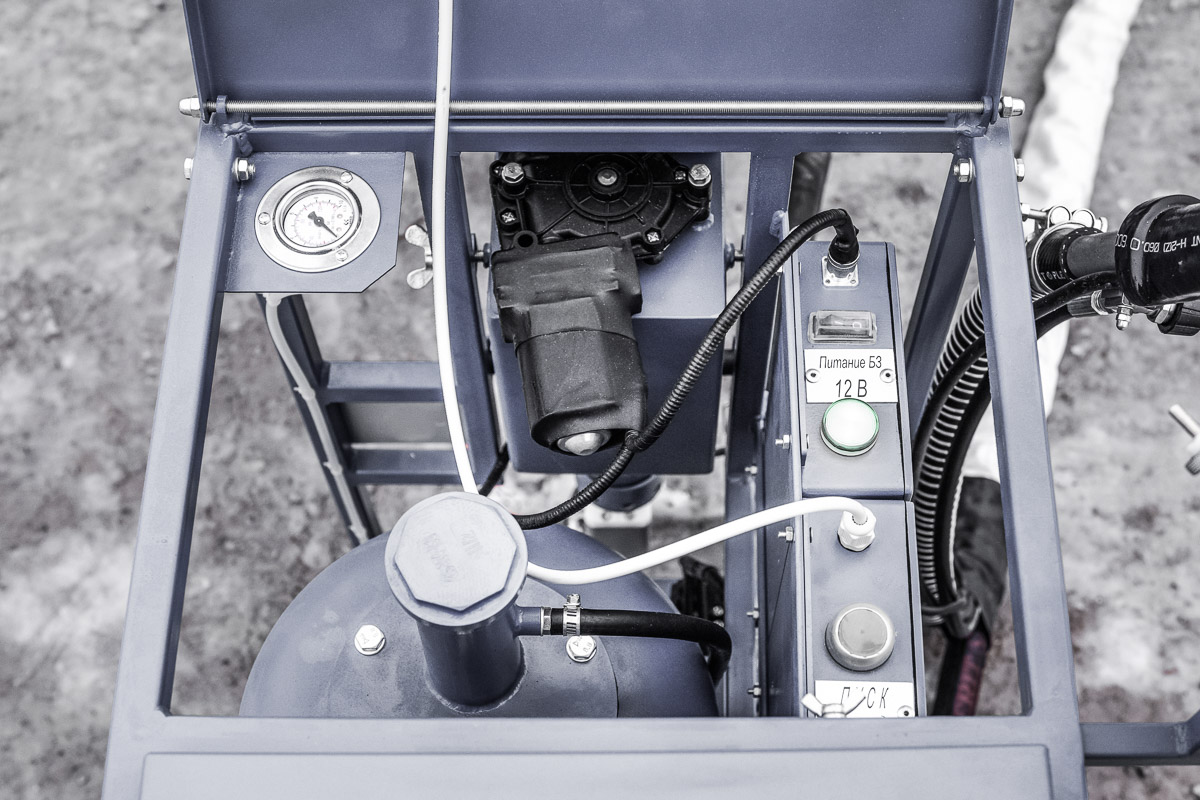

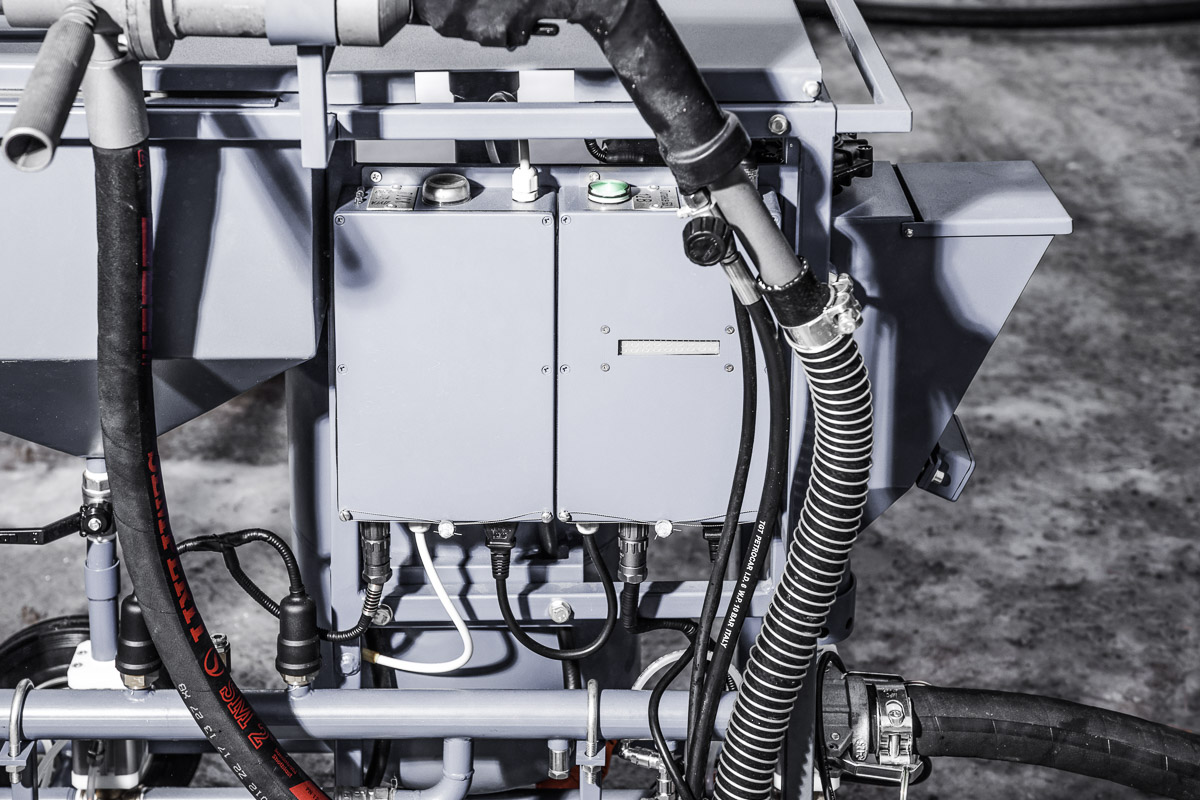

Complete safety and ease of use of PRANS HSS X7 and X8 equipment

Quality of Treatment SA 3+

The quality of surface treatment is guaranteed at the level SA 3 and higher (a potential of 0.7-0.8 V is formed on the surface) without any kind of contamination and oxide films

Low Abrasives Consumption

Consumption of any abrasive required for high-quality surface preparation is several times less.

Two Processes.

One Unit

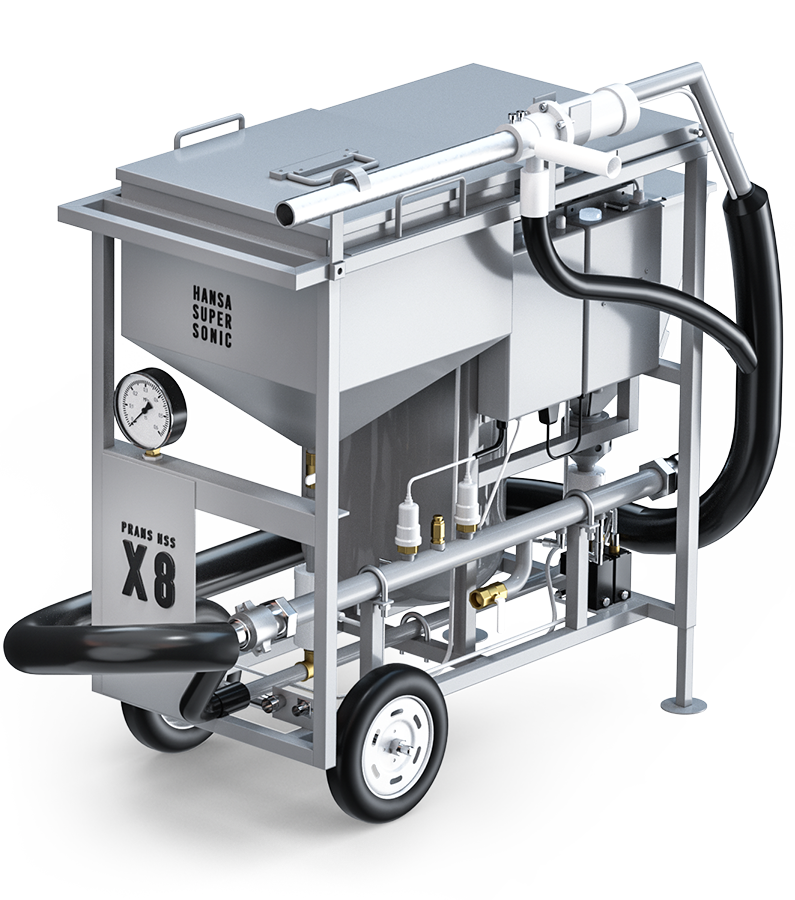

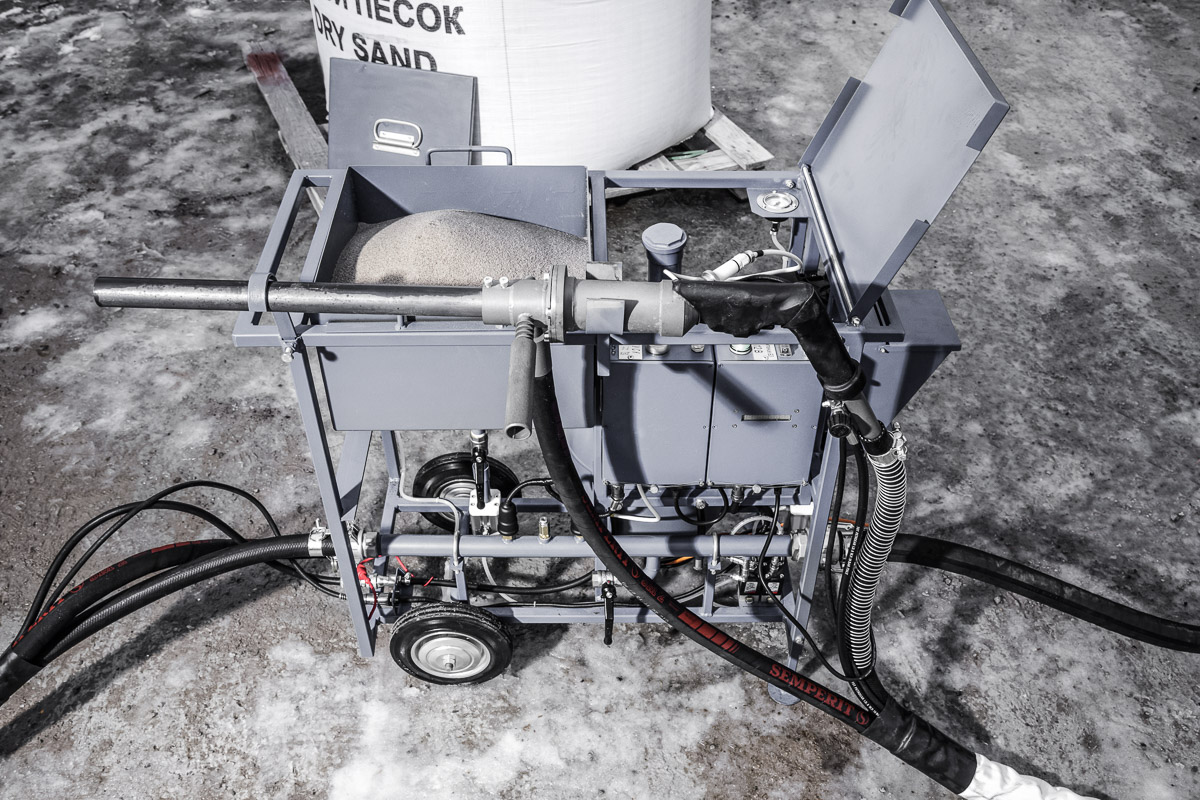

The PRANS HSS X8 unit is designed for thermo-abrasive cleaning of surfaces and structures made of various materials from any coating, oxide films, limescale, fuel oil deposits and other contaminants with subsequent application of a protective zinc coating onto the cleaned metal parts.

Switching between cleaning and coating processes with no delay.

Switching process video:

Before & After Samples

Cleaned with HSS

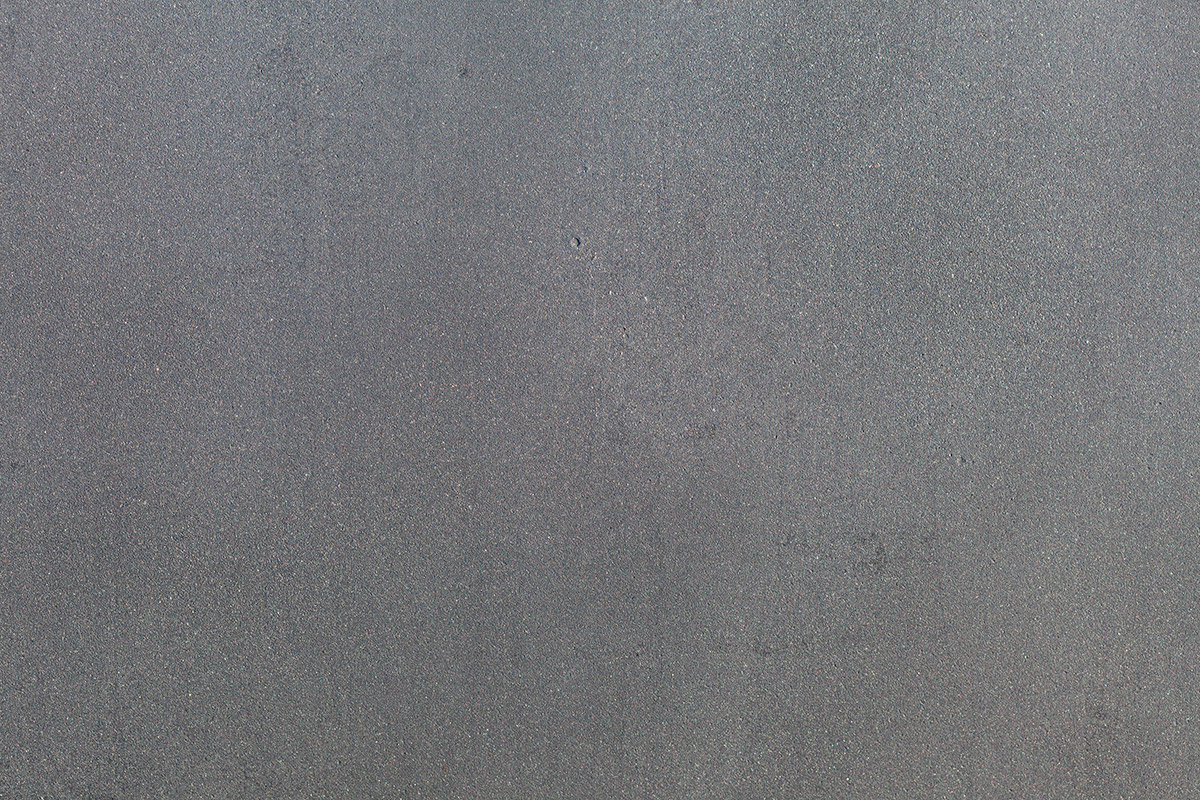

Cleaned with HSS

Original Surface

Original Surface

Cleaned with HSS

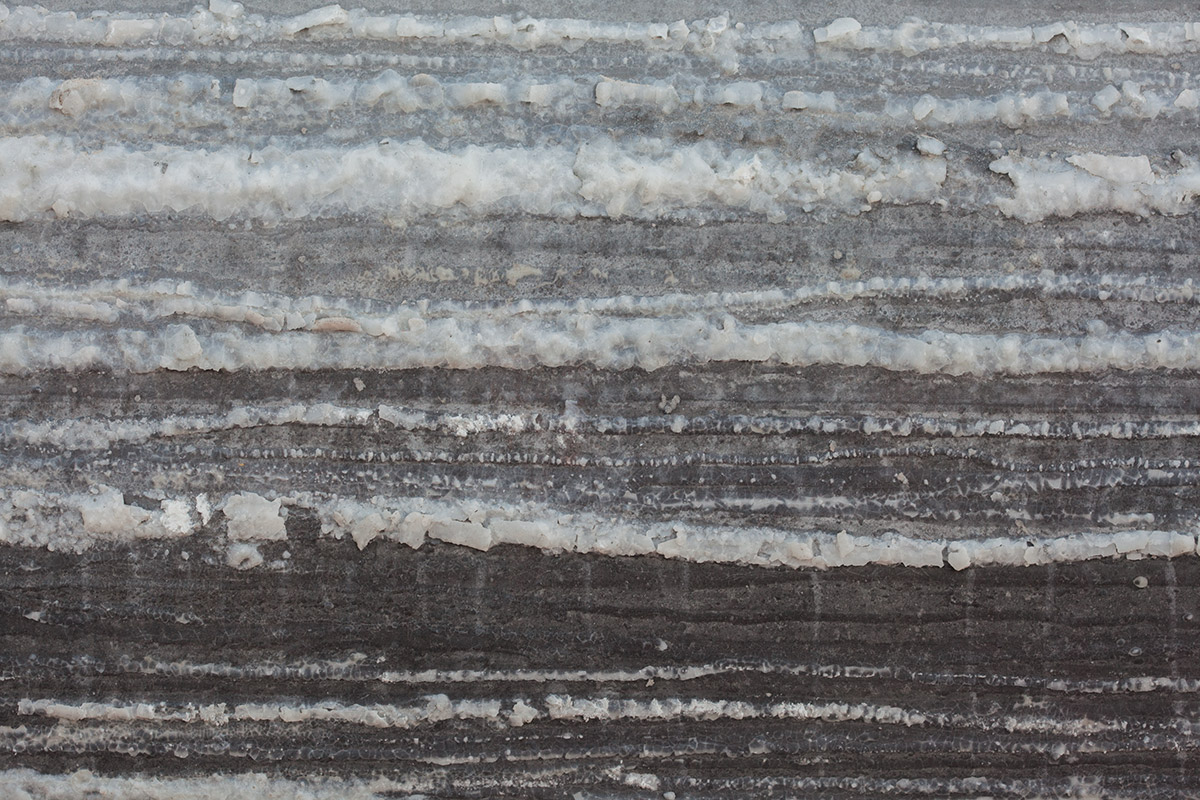

Cleaned with HSS

Original Surface

Original Surface

Cleaned with HSS

Cleaned with HSS

Original Surface

Original Surface

Technical Specs

220 V, 50 Hz

0.7–0.8 MPa

4.5–6.5 m3/min

2-3 hours

8.0–15.0 l/h

from -5°C to +30°C

20-40 m2/hour

1.0 mm

6–15 kg/m2